For over sixty years, Foremost has been supplying quality equipment designed to meet the needs of the plastics industry. Foremost currently offers three types of fluff feeders, each designed for specific applications.

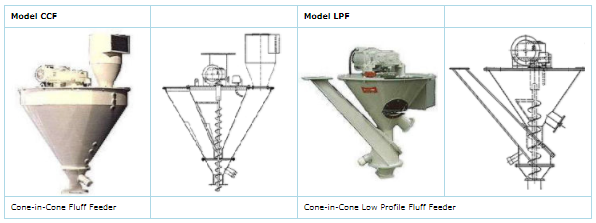

These include the standard model CFV-2 with Vector drive, the CCF cone in cone feeder and the LPF Low Profile type feeder.

These series of crammer feeders are force feeding devices that are designed to compact fluffy materials at the extruder screw to provide a uniform density and relatively consistent head pressure.

Our crammer feeders employ the use of a Flux Vector drive, a true torque device which enables the system to feed up to a 50% fluff/pellet blend with a consistent material density at the extruder throat. The benefits of this crammer feeder include true cramming action which provides relatively constant head pressure throughout the range of normal extruder needs.

| EXTRUDER SIZE | 1″ TO 3″ | OVER 3″ TO 6″ | OVER 6″ | ||

|---|---|---|---|---|---|

| Type | Model Designation | Model Range | Comments: | ||

| Crammer Feeder | CFV- | CFV-1 | CFV-2 | CFV-3 | True Crammer Feeder, constant feed/head pressure, automatically tracks extruder speed, mixed material required (no proportioning or blending) |

Cone-In-Cone Fluff Feeder | CCF- | CCF-1 | CCF-2 | CCF-3 | Pellet Fluff Proportioning, adds fluff to pellet flow stream, some fluff compaction but no real cramming action or extruder speed tracking (speed following available as an option) |

Low Profile Fluff Blender | LPF- | LPF-1 | LPF-2 | LPF-3 | Same as CCF Models but low profile/low volume configuration |