The HD-6C is specifically designed to reduce dust and fines. Granulators naturally produce dust, especially with dull knives and improper knife gap. Dust is greatly reduced with the HD-6C. A three-bladed rotor is used to “shear” material instead of “take a bite” out of the material. The dairy package of this model is especially popular.

- BLOW MOLDING TRIM & START UP SCRAP

- THRU PUT APPROX. 450 LBS/HR

- 14” X 18” THROAT OPENING TO ACCOMMODATE LARGE

UNTRIMMED CONTAINERS - CONSULT FACTORY FOR SPECIFIC APPLICATIONS

- HIGH SHEAR KNIVES TO MINIMIZE FINES & DUST FOR PE AND PP

APPLICATIONS - OFFSET ROTOR DESIGN TO MINIMIZE FLYBACK

- HEAVY DUTY SELF ALIGNING ROLLER BEARINGS

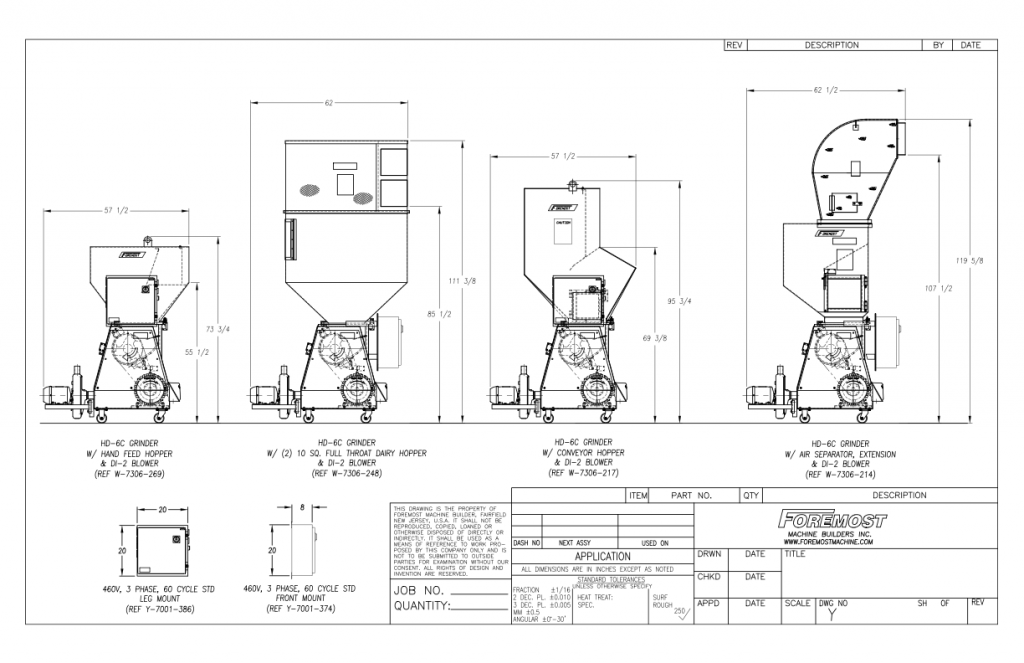

- HANDFEED HOPPER: (W-SK-7306-189-1) Heavy duty 7 ga. Hopper features are robust mounting flange, steel framed cleanout door with safety switch and curtain to prevent material flyback.

- DAIRY HOPPER II: (W-SK-7306-10) Full throat discharge hopper, circular split hopper, access door, dual baffles, constructed of heavy duty sheet and flattened expanded metal. (2) 10” inlets standard.

- CONVEYOR HOPPER: (W-7306-195) Heavy gauge alloy steel, welded construction. Hopper features are robust mounting flange, steel framed cleanout door with safety switch, and vinyl curtain to prevent material kick back. This hopper has an angled conveyor shelf for mounting a feed conveyor to the grinder.

- AIR SEPARATOR: (W-5007-107) Select inlet from next page. Heavy duty perforated steel hopper with inlet mounting plate and cleanout doors. Must be mounted to the hand feed hopper or the air separator extension. Standard is (2) 10″ square.

- AIR SEPARATOR EXTENSION: (W-SK-7306-130) Heavy duty 7 ga. Hopper features are robust mounting flange, steel framed cleanout door with safety switch. Baffle to prevent material flyback.

- MATERIAL INFEED ALARM:

Photo-Eye sensor, with remote alarm panel to indicate material buildup at grinder hopper.QUIET MODEL AHD-6C GRANULATOR, WITH SOUND ATTENUATION - BLOWER:

Alternative blower models available. - MODEL 250 CYCLONE:

For regrind discharge. Other sizes are available. - ELECTRICS:

230V, 3 Phase, 60 Cycle - ADAPTORS:

Extensions available to change height of grinder. - PANEL MOUNT:

Talk to a sales representative about ways to mount the control panel on or around the grinder. - INFEED BELT CONVEYOR:

Different arrangements available. - DUAL SET POINT AMMETER:

To regulate infeed conveyor.

FEED: TANGENTIAL

HOPPER: HAND FEED

THROAT: 14”X 18”

ROTOR SHAFT SIZE: 3”

ROTOR: THREE BLADED, STRAIGHT RIBBED, SINGLE

DRIVEN

ROTOR SPEED: 438 RPM

KNIVES: THREE 16” ROTARY HI-SHEAR

TWO 18” BED

CUTTING DIAMETER: 12”

FLYWHEEL DIAMETER: 13”

SCREEN: 05/16”, 40% OPEN – STANDARD

POWER: 15 HP 1800 RPM TEFC MOTOR

ELECTRICS: 460V, 3 PHASE, 60 CYCLE (STANDARD) SAFETY SWITCHES: WIRED TO PREVENT OPERATION OF GRINDER WHEN HOPPER IS OPEN OR IF SCREEN IS EXPOSED CONTROLS (UL LISTED): NEMA 12 PANEL W/FUSED DISCONNECT & INTERLOCKED STARTER FOR GRINDER & OPTIONAL BLOWER MOTOR. CONTROL

VOLTAGE 120V

BLOWER: DI-2 IMPELLER MOUNTED TO GRINDER

AIR SEPARATOR HOPPER INLET

The air separator hopper is available with multiple inlet arrangements as listed below.

| # of Inlets | NONE | 1 | 2 | 3 | 1 | 1 |

|---|---|---|---|---|---|---|

| Size | Blank Plate | 10” Square | 10” Square | 10” Square | 12” Square | 12” Square RH |

| # of Inlets | 1+1 | 2 | 1 | 1 | 2 | 1 |

|---|---|---|---|---|---|---|

| Size | (1) 12” Square & (1) 10” Square | 12” Square | 10” Outer Dia. | 11” Outer Dia. | 11 ½ Inner Dia. | 12” Outer Dia. |