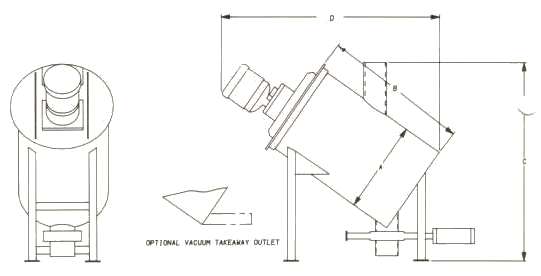

The Inclined Barrel Mixer consists of an inclined cylindrical housing with a center mounted agitator. The constant speed A.C. drive is mounted on the bolted cover which has a hinged access door and a safety switch. The single agitator is designed for efficient mixing at low tip speed. This design decreases power requirements as well as material degradation due to attrition, impact, or temperature rise.

The rugged welded carbon steel housing is supplied with integral leg supports for floor or machine mounting. A 6″ dia. inlet and a 6″ dia. outlet with a manual slide gate dump valve are standard. The standard mixer control is timer based, but may be designed for on-demand operation or as part of Foremost’s line of volumetric or gravimetric multi-ingredient blenders.

Options include positive closure inlet and dump valves, as well as in-line vacuum loading and unloading.

E = Electrical M = Mechanical.

E • NEMA 12 control panel.

E • Mixer timer controls.

E • Access door safety switch.

E • Welded carbon steel construction.

E • 6″ dia. inlet.

E • 6″ dia. bottom outlet with manual slide gate.

E • Integral support legs.

- Stainless steel construction for sanitary applications.

- Foremost vaccum changers with controls for automatic loading and unloading.

- Controls for on-demand, continuous automatic batching.

- Can be supplied for hazardous areas.

Foremost VBM vacuum barrel mixers are used as mixing vacuum receivers and are frequently combined with Foremost weigh blenders. They are available in all the same sizes as our line of inclined barrel mixers. In many cases, materials being conveyed or blended have varying physical sizes and weights and tend to segregate when being pneumatically conveyed to the process machinery. To deal with this we mount the mixer directly above the process machine hopper and convey the entire batch of blended material over the press where it is mixed and then dumped into the hopper. This insures that a homogeneous blend of material is being delivered to the press. A vacuum chamber is integrated into the inlet of the mixer. The discharge of the mixer is pneumatically sealed allowing it to hold vacuum.

| Model # | A | B | C | D | Working Capacity (cu ft) | Motor HP |

|---|---|---|---|---|---|---|

| MBM-150 | 12″ | 24″ | 18″ | 44″ | 0.75 | 1/2 HP |

| BM-275 | 16′ | 24″ | 26″ | 44″ | 1.5 | 3/4 HP |

| BM-650 | 24″ | 26″ | 44″ | 46″ | 4 | 1-1/2 |

| BM-1000 | 24″ | 37″ | 49″ | 49″ | 5 | 3 |

| BM-1500 | 30″ | 37″ | 58″ | 58″ | 8 | 3 |

| BM-2100 | 36″ | 36″ | 58″ | 60″ | 10 | 5 |