Menu

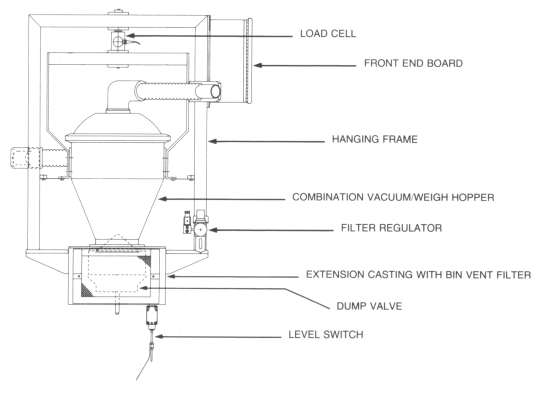

Our Weight Inventory Control Systems are an advanced design which provides for the utmost accuracy and dependability. Rugged construction assures years of trouble-free service. The material is pulled into the vacuum chamber and is held momentarily while the weight is added to the accumulator register. The vacuum chamber does not dump its contents until the accumulator acknowledges receipt of the added weight. In normal operations, the chamber is filled by time using the station timer in the vacuum loader panel. As an option, a keyboard is provided whereby authorized personnel can use a key to enter a pre-set weight. With this option, the vacuum loader will run until the chamber is full to capacity.

Features

Assembly

Options

Draft Weigher

Features

1 Part in. 10,000 Graduations

Load Cell Mount Minimizes the Chance of Damage

Auto Zero Tracking

Load Cell Linearization

Data Output, RS232C, 20MA Current Loop

Auto Accumulation

Remote Mounted Panel

Assembly

- Rugged Aluminum Tube Construction

- Standard Size Chambers, 0.2 cu. ft., 0.6 cu. ft., 2 cu. ft., 4 cu. ft., 6 cu. ft.

- Designed for Years of Trouble Free Service

Options

- Stainless Steel Construction

- Filter Bags for Powder Applications

- Positive Closure Knife Gate Discharge

- Up to Four WICS Units Utilizing a Common Weigh Meter Panel

Draft Weigher

- Mechanically Identical to the WICS

- Loads Material up to a Preprogrammed Set Point in Multiple Drafts

- ± 0.5% Gross Setpoint Accuracy