Pneumatic Conveyors

Central Vacuum Systems

Central Vacuum Loaders

Foremost manufactures central vacuum loaders and conveying receivers for the transporation of raw material pellets and reclaim material from a storage silo to a blender, from one process station to another, and/or to the final processing point.

Self-Contained Vacuum Loaders - B Series

Foremost manufactures self-contained vacuum loaders for the transportation of raw material pellets and reclaim material from a storage silo to a blender, from one process station to another, and/or to the final processing point.

Vacuum Chambers

A typical target weight loss weight blender has each metering feeder mounted to an independent, load cell supported, weighing hopper.

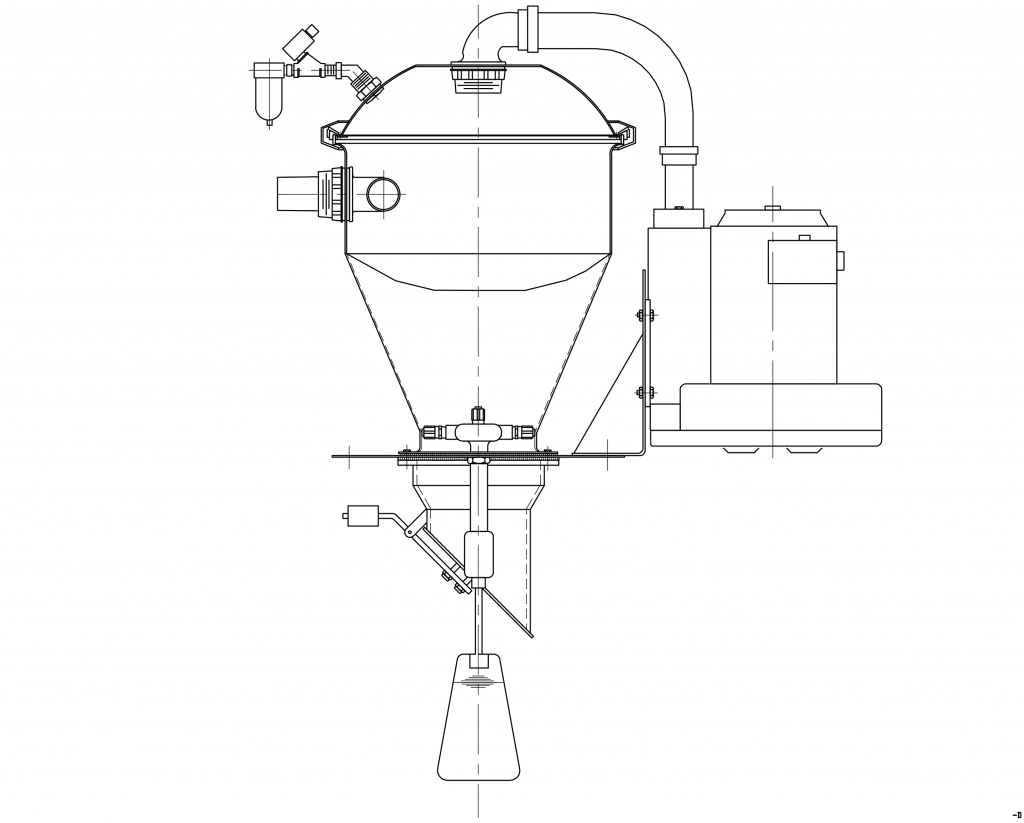

Self-Contained Vacuum Loaders - C Series

Powder Type Vacuum Chamber

The Vacuum Powder Chamber model VPC is a low profile, low maintenance filter receiver designed for a wide range of material handling operations.

Railcar Unloaders

Straight Walled Vacuum Chamber

CF Series Vacuum Loader

The CF and CMF Series Centrifugal Blower packages are an inexpensive, low maintenance alternative to positive displacement pump type vacuum loading systems.

Control Panels

The Format IV is a user-friendly PLC based vacuum loading system controller. The Format IV has the capability of controlling up to 3 vacuum pumps and 27 loading stations in any combination of pumps and stations as required.

Additional Components

Our additional components include sunction lances, gaylord tilters, couplings, vacuum trays, bin vent filters, and more.